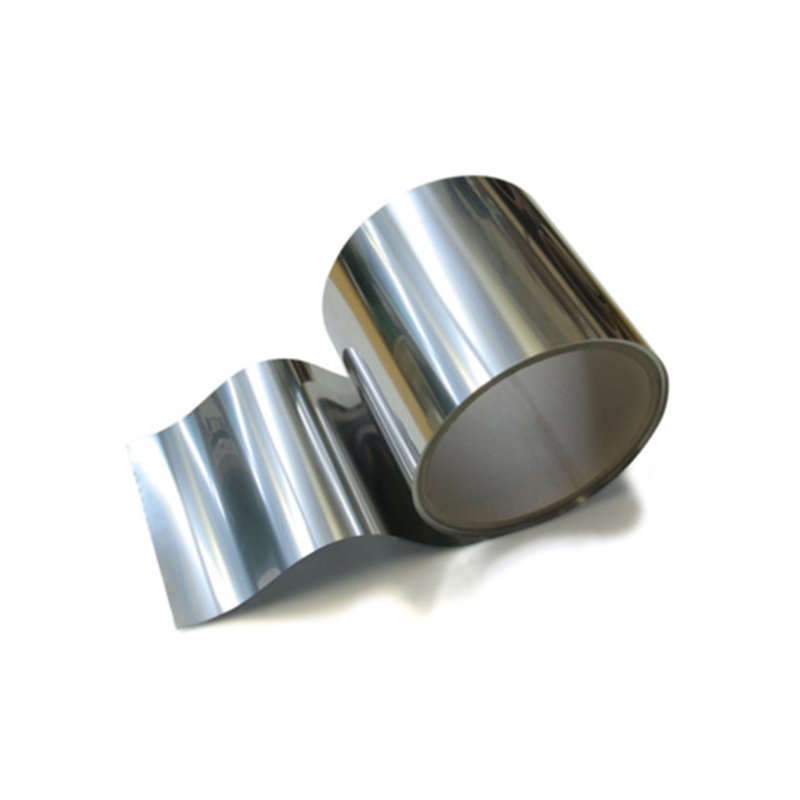

Igwe anaghị agba nchara gasket finishing àgwà factory kpọmkwem ahịa

Njirimara anụ ahụ

1. Enwere ion chloride na gburugburu ebe ọrụ.

A na-ahụ ion chloride na nnu, ọsụsọ, mmiri oké osimiri, ifufe, ala, wdg. Igwe anaghị agba nchara corrodes ngwa ngwa n'ihu ọnụnọ nke ion chloride karịa ígwè dị nro nkịtị.

Ya mere, iji gburugburu igwe anaghị agba nchara nwere ihe ndị a chọrọ, na mkpa na-ehichapụkarị, wepụ ájá, na-adị ọcha na nkụ.(Nke a na-enye ya "ojiji na-ekwesịghị ekwesị.")

Enwere ihe atụ na United States: ụlọ ọrụ jiri akpa osisi oak jide ihe ngwọta nwere ion chloride.Ejirila akpa ahụ ihe karịrị otu narị afọ ma zubere ka edochie ya na 1990s.N'ihi na ihe osisi oak ahụ adịchaghị nke oge a, akpa ahụ mebiri emebi wee gbapụta ụbọchị 16 ka ejiri igwe anaghị agba nchara dochie ya.

2. Ọ dịghị ọgwụgwọ ọgwụgwọ.

Ihe alloy agbazeghị n'ime matriks ahụ, na-ebute ọdịnaya alloy dị ala na nhazi matriks na nguzogide corrosion na-adịghị mma.

3. Ihe ndị dị otú ahụ na-enweghị titanium na niobium nwere ọdịdị ọdịdị nke corrosion intergranular.

Mgbakwunye nke titanium na niobium, jikọtara ya na ọgwụgwọ kwụsiri ike, nwere ike ibelata corrosion intergranular.

Na ikuku ma ọ bụ chemical corrosion ọkara nwere ike iguzogide corrosion nke a elu alloy ígwè, igwe anaghị agba nchara bụ a mara mma elu na ezi corrosion eguzogide, adịghị ga-plated na ndị ọzọ elu ọgwụgwọ, na-egwu pụta ụwa Njirimara nke igwe anaghị agba nchara, na-eji na. ọtụtụ akụkụ nke ụdị nchara, nke a na-akpọkarị igwe anaghị agba nchara.N'aha arụmọrụ nke 13 chromium ígwè, 18-8 chromium nickel ígwè na ndị ọzọ elu alloy ígwè.

Site metallographic ele ihe anya, n'ihi na igwe anaghị agba nchara nwere chromium na n'elu nke e guzobere a nnọọ mkpa chromium film, ihe nkiri kewapụrụ na oxygen na ígwè mbuso agha nke corrosion iguzogide.

Iji nọgide na-enwe nguzogide corrosion dị na igwe anaghị agba nchara, ígwè ga-enwerịrị ihe karịrị 12% chromium.

304 igwe anaghị agba nchara Shim Plates bụ igwe anaghị agba nchara zuru ụwa ọnụ, nke a na-ejikarị eme ihe na akụrụngwa na akụkụ chọrọ akụrụngwa zuru oke (nguzogide corrosion na formability).

304 igwe anaghị agba nchara bụ akara igwe anaghị agba nchara emepụtara dịka ụkpụrụ ASTM siri dị na United States.304 bụ nke China 0Cr19Ni9 (0Cr18Ni9) igwe anaghị agba nchara.304 nwere 19% chromium na 9% nickel.

304 bụ igwe anaghị agba nchara/okpomọkụ na-ejikarị eme ihe.Ejiri ya na akụrụngwa mmepụta nri / akụrụngwa kemịkalụ xiton / ike nuklia, wdg.

304 dabara na akara China 0Cr18Ni9,1Cr18Ni9Ti, ọdịnaya carbon ≤0:08%

304Lstainless steel Shim Plates bụ ụdị dị iche iche nke igwe anaghị agba nchara 304 Shim Plates igwe anaghị agba nchara nwere ọdịnaya carbon dị ala ma ejiri ya maka ngwa ịgbado ọkụ.Ọdịnaya carbon dị ala na-ebelata oke mmiri nke carbide na mpaghara okpomọkụ emetụtara dị nso na weld, nke nwere ike ibute corrosion intergranular (ịgbado ọkụ) na igwe anaghị agba nchara na mpaghara ụfọdụ.

Oke

| T | isi ike | isi ike | Ọnọdụ ọgwụgwọ okpomọkụ na-eme ka mmiri ozuzo sie ike | eduzi% | ||||||

| isi ike | isi ike | Mkpụrụ ikeN/mm | Ike tensileN/mm | elongation% | Ọgwụgwọ okpomọkụ | hardnessHV | Mkpụrụ ikeN/mm | Ike tensileN/mm | ||

| 301-CSP | 1/2H | 340± 30 | ≥510 | ≥930 | ≥10 | - | - | - | - | 2.3 |

| 3/4H | 400±30 | ≥745 | ≥1130 | ≥5 | - | - | - | - | 2.3 | |

| H | 460± 30 | ≥1030 | ≥1320 | - | - | - | - | - | 2.3 | |

| EH | 510±20 | ≥1275 | ≥1570 | - | - | - | - | - | 2.3 | |

| SEH | ≥530 | ≥1450 | ≥1740 | - | - | - | - | - | 2.3 | |

| 304-CSP | 1/2H | 280± 30 | ≥470 | ≥780 | ≥6 | - | - | - | - | 2.3 |

| 3/4H | 340± 30 | ≥665 | ≥930 | ≥3 | - | - | - | - | 2.3 | |

| H | ≥370 | ≥880 | ≥1130 | - | - | - | - | - | 2.3 | |

| 631-CSP | 0 | ≤200 | - | ≤1030 | ≥20 | TH1050RH950 | ≥345≥392 | ≥960≥1030 | ≥1140≥1230 | 2.3 |

| 1/2H | 375± 25 | - | ≥1080 | ≥5 | CH | ≥380 | ≥880 | ≥1230 | 2.3 | |

| 3/4H | 425±25 | - | ≥1180 | CH | ≥450 | ≥1080 | ≥1420 | 2.3 | ||

| H | ≥450 | - | ≥1420 | CH | ≥530 | ≥1320 | ≥1720 | 2.3 | ||