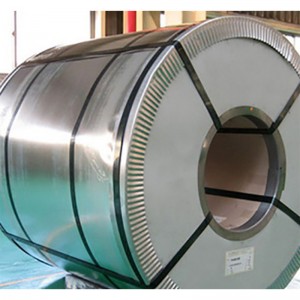

321 igwe anaghị agba nchara tube tube mkpanaka eriri ọnụ ọnụ

Nkọwa

321 igwe anaghị agba nchara coilis titanium kwụsie ike austenitic igwe anaghị agba nchara nwere ezigbo nguzogide corrosion n'ozuzu.Ọ nwere ezigbo nguzogide corrosion intergranular mgbe ekpughere ya na okpomọkụ na oke mmiri ozuzo chromium carbide nke 800 - 1500°F (427-816°C).Alloy na-eguzogide oxidation ruo 1500°F (816°C) ma nwee ihe mgbawa dị elu na mgbawa nrụgide karịa alloys 304 na 304L.Ọ nwekwara ezigbo okpomọkụ siri ike.

Alloy 321H (UNS S 32109) igwe anaghị agba nchara bụ ụdị carbon dị elu (0.04 - 0.10) nke alloy.Emepụtara ya maka nkwụsi ike na-akpụ akpụ yana maka ike dị elu na okpomọkụ karịa 1000oF (537°C).N'ọtụtụ oge, ọdịnaya carbon nke eriri igwe na-enyere asambodo abụọ aka.

Alloy 321 igwe anaghị agba nchara enweghị ike isi ike site na ọgwụgwọ okpomọkụ, naanị site na ịrụ ọrụ oyi.Enwere ike ịgbanye ya ngwa ngwa ma hazie ya site na omume nrụpụta ụlọ ahịa ọkọlọtọ.

Otu ISO 9001: 2008 Certified Company, Savoy piping Inc., bụ onye na-eduga n'ahịa, onye na-ebubata na onye mbupụ nke ASTM A240 321 igwe anaghị agba nchara.A na-ebipụ eriri igwe anaghị agba nchara 321 na nkọwapụta gị wee wepụta ya na akụkọ nyocha igwe igwe zuru oke.Ogologo omenala na obosara ruo 2000 mm nwere ike ime ka ọ dị.Mbupụ bụ Ọpụrụiche Anyị!na anyị nwere ike isite ọtụtụ ike ịchọta akara ule na ma ọ bụ na-abụghị ọkọlọtọ nha izute pụrụ iche chọrọ nke anyị ahịa.Enwere ike bee ASTM SS 321 Steel Coil ka ọ bụrụ nha site n'enyemaka nke nka dị ukwuu na nhazi ngwaahịa igwe.

Ngwaahịa anyị nke ASTM A240 321 igwe anaghị agba nchara gụnyere ọkpụrụkpụ nke 6mm ruo 80mm na obosara nke 1250mm, 1500mm, 2000mm.

Dị Ọkwa Ndị Ọzọ

Enwere ike nweta akara ule ọzọ na eriri igwe anaghị agba nchara 321.

| EN-ọkọlọtọ | EN-ọkọlọtọ | ọkwa SAE | UNS |

| 1.4109 | X65CrMo14 | 440A | S44002 |

| 1.4112 | X90CrMoV18 | 440B | S44003 |

| 1.4125 | X105CrMo17 | 440C | S44004 |

| 440F | S44020 | ||

| 1.4016 | X6Cr17 | 430 | S43000 |

| 1.4408 | GX 6 CrNiMo 18-10 | 316 | S31600 |

| 1.4512 | X6CrTi12 | 409 | S40900 |

| 410 | S41000 | ||

| 1.4310 | X10CrNi18-8 | 301 | S30100 |

| 1.4318 | X2CrNiN18-7 | 301LN | |

| 1.4307 | X2CrNi18-9 | 304L | S3043 |

| 1.4306 | X2CrNi19-11 | 304L | S30403 |

| 1.4311 | X2CrNiN18-10 | 304LN | S30453 |

| 1.4301 | X5CrNi18-10 | 304 | S30400 |

| 1.4948 | X6CrNi18-11 | 304H | S30409 |

| 1.4303 | X5CrNi18-12 | 305 | S30500 |

| X5CrNi30-9 | 312 | ||

| 1.4841 | X22CrNi2520 | 310 | S31000 |

| 1.4845 | X 5 krNi 2520 | 310S | S31008 |

| 1.4541 | X6CrNiTi18-10 | 321 | S32100 |

| 1,4878 | X12CrNiTi18-9 | 321H | S32109 |

| 1.4404 | X2CrNiMo17-12-2 | 316L | S31603 |

| 1.4401 | X5CrNiMo17-12-2 | 316 | S31600 |

| 1.4406 | X2CrNiMoN17-12-2 | 316LN | S31653 |

| 1.4432 | X2CrNiMo17-12-3 | 316L | S31603 |

| 1.4435 | X2CrNiMo18-14-3 | 316L | S31603 |

| 1.4436 | X3CrNiMo17-13-3 | 316 | S31600 |

| 1.4571 | X6CrNiMoTi17-12-2 | 316 Ti | S31635 |

| 1.4429 | X2CrNiMoN17-13-3 | 316LN | S31653 |

| 1.4438 | X2CrNiMo18-15-4 | 317L | S31703 |

| 1.4362 | X2CrNi23-4 | 2304 | S32304 |

| 1.4462 | X2CrNiMoN22-5-3 | 2205 | S31803/S32205 |

| 1.4501 | X2CrNiMoCuWN25-7-4 | J405 | S32760 |

| 1,4539 | X1NiCrMoCu25-20-5 | 904L | N08904 |

| 1.4529 | X1NiCrMoCuN25-20-7 | N08926 | |

| 1.4547 | X1CrNiMoCuN20-18-7 | 254SMO | S31254 |